2 kegs in keezer, one with some blonde ale, one with more doppelbock

5 gallons baltic porter lagering, 2-3 weeks out

5 gallons SAB clone in primary, 1-2 weeks out

2 bombers saison

7 bottles APA

4 bottles tripel

8 bottles RIS

Should bottle some doppelbock for aging

Should make a Saison - maybe add some pumpkin/spice?

Should make a batch of Pilsner

Should make a Belgian Dubbel

This is just my brewing notebook, which works better than my old spiral. I have no other motivation for keeping this.

Showing posts with label General. Show all posts

Showing posts with label General. Show all posts

Wednesday, September 5, 2018

Friday, July 6, 2018

Current Inventory

5 gallons doppelbock in secondary

3-4 gallons marzen on tap

1-1/2 cases saison

3/4 case tripel

1 case RIS

brew day tomorrow 5 gallons APA

3-4 gallons marzen on tap

1-1/2 cases saison

3/4 case tripel

1 case RIS

brew day tomorrow 5 gallons APA

Keezer notes

Exchanged 10 lb CO2 cylinder at Terrace Supply in Villa Park for $56 on 7/5. Old cylinder was overdue for testing, costing extra $20.

Monday, September 4, 2017

Current process

Today I am starting a lager, and took some pictures to document the day. Many things have changed since I started 5 years ago, but many stay the same.

For starters, I now use this kitchenaid mill attachment to grind my grain. I use the coarsest setting, which gives a consistent pretty fine crush, with good efficiency and minimal stuck sparge. Downside is the cup only holds about a pound of grain, so I have to keep feeding it off the scale every few minutes.

I still just use a pot on the stove as my HLT, and transfer infusion water into my tun on top of the grain with a quart pyrex pitcher. Typically I heat the HLT to about 15 df above my first rest temperature, then bring it to a boil to infuse to higher rest temps. Any salts go into the grain/mash, where I sometimes test the pH. I use CaCl, gypsum, or baking soda, depending on the application. I love the stainless spatula for stirring in the mash, which I have used since day 1. I also now have a homemade maple wooden spoon that I use for larger mashes when the stainless doesn't reach the bottom .

I still use the lauter manifold I built when I first started, it works great in the gott cooler I use as the mash tun. Sparge water is transferred using the pyrex pitcher from the 170 df HLTs. I vorlauf about 3 or 4 quarts, depending on how the wort looks.

For this batch, there is a lot of pils, so I want to drive off as much dms as I can, so I use 2 pots for a good portion of the boil. The biggest stove burner is 17,000 btu/hr, which produces less than the roiling boil I prefer for 5 gallons. It works great for 3 or 4 gallons, but 5 gallons is more of a simmer. With 2 row or maris otter, the one big pot is fine, but pils, splitting is better. Also, I typically use 3 burners to get it up to a boil, which otherwise takes forever.

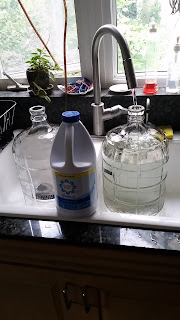

I use bleach for sanitizing on brew day. I came full circle, using starsan for a while, but started having way too much contamination because it doesn't clean, it only sanitizes. With bleach, when you leave things soaking for 20 minutes, they come out clean. With starsan, things had a coating of beer on them, so I really should have added pbw or something to the cleaning process if I wanted to continue with it. I still use it for bottling, but I am careful to brush out bottles before putting them in storage. Note I also still use glass carboys for fermentation. I have cracked a couple over the years, but with careful handling, I feel better about them being clean.

Here's an addition for lagering, a pre-chiller coil. I have a copper coil in an ice bath that chills the tap water before it gets to the wort chiller. In winter months, I can get down to the mid 50s, but in summer, it is still a push to get below 70 df with tap water for chilling.

I still aerate wort for pitching in the same costco milk jug I have used since day 1, about 25 shakes of a half-ful jug does the trick.

I now have 2 fermentation chambers in the basement. The first is an old ice-cream freezer that I use for lagering only, it holds up to 3 3-gallon carboys. It is only set up to cool, it doesn't warm. The second unit is a college-dorm fridge with a plywood case extending the front, it holds 2 5-gallon carboys, and can either chill or heat, as I added a reptile heater bulb into the side of the box. The temp controls are just two generic fish-tank controllers rigged to hold the appropriate temperature. I can have up to 19 gallons in fermentation at any time, but usually have 11 or so, 2 carboys in each chamber.

I bought a funnel-filter to filter out wort from the trub in the bottom of the pot. Sometimes it takes overnight.

While I still bottle using table sugar as primer for natural carbonation, my latest toy is this keezer I bought second-hand from a guy for $550 and some homebrew. I priced out the components, which added up to about $1000 worth of stuff, so I think I did OK. I bought the kegs separately. Kegging is way easier and makes better beer. Any beer that is good cold goes into a keg.

So now I make 5+ gallon batches, maybe every 2-3 weeks. I am a lot more confident on my recipes, and rarely have a batch that I have to choke down, although it still happens occasionally.

For starters, I now use this kitchenaid mill attachment to grind my grain. I use the coarsest setting, which gives a consistent pretty fine crush, with good efficiency and minimal stuck sparge. Downside is the cup only holds about a pound of grain, so I have to keep feeding it off the scale every few minutes.

I still just use a pot on the stove as my HLT, and transfer infusion water into my tun on top of the grain with a quart pyrex pitcher. Typically I heat the HLT to about 15 df above my first rest temperature, then bring it to a boil to infuse to higher rest temps. Any salts go into the grain/mash, where I sometimes test the pH. I use CaCl, gypsum, or baking soda, depending on the application. I love the stainless spatula for stirring in the mash, which I have used since day 1. I also now have a homemade maple wooden spoon that I use for larger mashes when the stainless doesn't reach the bottom .

I still use the lauter manifold I built when I first started, it works great in the gott cooler I use as the mash tun. Sparge water is transferred using the pyrex pitcher from the 170 df HLTs. I vorlauf about 3 or 4 quarts, depending on how the wort looks.

For this batch, there is a lot of pils, so I want to drive off as much dms as I can, so I use 2 pots for a good portion of the boil. The biggest stove burner is 17,000 btu/hr, which produces less than the roiling boil I prefer for 5 gallons. It works great for 3 or 4 gallons, but 5 gallons is more of a simmer. With 2 row or maris otter, the one big pot is fine, but pils, splitting is better. Also, I typically use 3 burners to get it up to a boil, which otherwise takes forever.

I use bleach for sanitizing on brew day. I came full circle, using starsan for a while, but started having way too much contamination because it doesn't clean, it only sanitizes. With bleach, when you leave things soaking for 20 minutes, they come out clean. With starsan, things had a coating of beer on them, so I really should have added pbw or something to the cleaning process if I wanted to continue with it. I still use it for bottling, but I am careful to brush out bottles before putting them in storage. Note I also still use glass carboys for fermentation. I have cracked a couple over the years, but with careful handling, I feel better about them being clean.

Here's an addition for lagering, a pre-chiller coil. I have a copper coil in an ice bath that chills the tap water before it gets to the wort chiller. In winter months, I can get down to the mid 50s, but in summer, it is still a push to get below 70 df with tap water for chilling.

I still aerate wort for pitching in the same costco milk jug I have used since day 1, about 25 shakes of a half-ful jug does the trick.

I now have 2 fermentation chambers in the basement. The first is an old ice-cream freezer that I use for lagering only, it holds up to 3 3-gallon carboys. It is only set up to cool, it doesn't warm. The second unit is a college-dorm fridge with a plywood case extending the front, it holds 2 5-gallon carboys, and can either chill or heat, as I added a reptile heater bulb into the side of the box. The temp controls are just two generic fish-tank controllers rigged to hold the appropriate temperature. I can have up to 19 gallons in fermentation at any time, but usually have 11 or so, 2 carboys in each chamber.

I bought a funnel-filter to filter out wort from the trub in the bottom of the pot. Sometimes it takes overnight.

While I still bottle using table sugar as primer for natural carbonation, my latest toy is this keezer I bought second-hand from a guy for $550 and some homebrew. I priced out the components, which added up to about $1000 worth of stuff, so I think I did OK. I bought the kegs separately. Kegging is way easier and makes better beer. Any beer that is good cold goes into a keg.

So now I make 5+ gallon batches, maybe every 2-3 weeks. I am a lot more confident on my recipes, and rarely have a batch that I have to choke down, although it still happens occasionally.

Thursday, July 21, 2016

Inventory/what's next

Inventory during Dry July, 2016

About 5 gallons Doppelbock in secondary/lagering

Belgian Abbey - 1-1/4 case, case of bombers, 3 loose

Irish Red - 1-1/2 case

APA - 1-1/4 case

Pils - 1-3/4 case

Saison - 1/2 case

Schwarzbier - 1/2 case

Witbier - 5 loose

1 case empties

Next brew day, (RI) stout or maybe another saison, also could use (baltic) porter, marzen, 103 nut brown.

About 5 gallons Doppelbock in secondary/lagering

Belgian Abbey - 1-1/4 case, case of bombers, 3 loose

Irish Red - 1-1/2 case

APA - 1-1/4 case

Pils - 1-3/4 case

Saison - 1/2 case

Schwarzbier - 1/2 case

Witbier - 5 loose

1 case empties

Next brew day, (RI) stout or maybe another saison, also could use (baltic) porter, marzen, 103 nut brown.

Thursday, June 30, 2016

Hand grenades

Early this summer, had 3 different beers explode in bottles. First time.

First was Tripel 132, then Hop Marzen 133, then APA 135.

The Tripel was multiple bottles/events, beer wasn't fully fermented before bottling, then a bit too much primer (compensating for slow winter carbonation). As soon as basement temps reached summer levels (ie, 60s) kablooey. What a mess.

Shortly after, the marzen had at least one, and maybe more go off. It's possible it was a chain reaction and just one bottle actually went off on its own. This batch was unevenly carbed, and heavily primed in winter conditions. It went off within a day or two of the Tripel.

Finally, a single APA went off, I didn't notice it for a while, because the mess was dry and moldy when I found it. That one was probably the final bottle filled, with extra sugar and junk from the bottom of the bucket, although I can't verify for sure.

The Tripel and Marzen I quickly refrigerated the remainders of the batch and choked it down cold as fast as I could. The APA I just left on the shelf, no more problems as of yet, although it was somewhat unevenly carbed.

Lessons learned: mix in priming sugar more effectively. Label final bottle or two for early consumption. Don't over-carb in winter months, just be patient and wait for the beer to carb up.

Also, I'm not very happy with Starsan. Things don't get clean, and sanitation is iffy. Need to go back to bleach and/or boiling stuff, although Starsan for final bottle prep may be OK.

Messy and dangerous business.

First was Tripel 132, then Hop Marzen 133, then APA 135.

The Tripel was multiple bottles/events, beer wasn't fully fermented before bottling, then a bit too much primer (compensating for slow winter carbonation). As soon as basement temps reached summer levels (ie, 60s) kablooey. What a mess.

Shortly after, the marzen had at least one, and maybe more go off. It's possible it was a chain reaction and just one bottle actually went off on its own. This batch was unevenly carbed, and heavily primed in winter conditions. It went off within a day or two of the Tripel.

Finally, a single APA went off, I didn't notice it for a while, because the mess was dry and moldy when I found it. That one was probably the final bottle filled, with extra sugar and junk from the bottom of the bucket, although I can't verify for sure.

The Tripel and Marzen I quickly refrigerated the remainders of the batch and choked it down cold as fast as I could. The APA I just left on the shelf, no more problems as of yet, although it was somewhat unevenly carbed.

Lessons learned: mix in priming sugar more effectively. Label final bottle or two for early consumption. Don't over-carb in winter months, just be patient and wait for the beer to carb up.

Also, I'm not very happy with Starsan. Things don't get clean, and sanitation is iffy. Need to go back to bleach and/or boiling stuff, although Starsan for final bottle prep may be OK.

Messy and dangerous business.

Thursday, February 12, 2015

Pending beers to make

Next up: Belgian tripel

After that, where to go?

Yeast use in reverse:

S-04

W1469

W2278lager

OYL500 (may be bad)

W1084

W3942

W1214

W2633lager

So the next up should be a Wit, but I have quite a bit in stock. After that, stout, saison, english brown, hoppy beer, then back to the top. Somewhere need to work in a dunkel.

2/14 - Tripel

2/21 - Witbier

2/28 - Stout

3/7 - Saison

3/14-21 Out of town

3/28 - Dunkel

4/4 - Nut Brown or Scottish

4/11 - SAB clone or IPA

After that, where to go?

Yeast use in reverse:

S-04

W1469

W2278lager

OYL500 (may be bad)

W1084

W3942

W1214

W2633lager

So the next up should be a Wit, but I have quite a bit in stock. After that, stout, saison, english brown, hoppy beer, then back to the top. Somewhere need to work in a dunkel.

2/14 - Tripel

2/21 - Witbier

2/28 - Stout

3/7 - Saison

3/14-21 Out of town

3/28 - Dunkel

4/4 - Nut Brown or Scottish

4/11 - SAB clone or IPA

Saturday, May 17, 2014

Monday, January 27, 2014

Whoops on the pils

So, I've been working away on my sack of Weyermann's pilsner thinking it was their bohemian pilsner. Wrong. It is a sack of their base german pils.

I spotted a sack of the bohemian variety at Chicago Brew Werks in Plainfield when I was there a couple weeks ago, and realized the labeling for the bohemian says 'bohemian'. The one I got just says 'pilsner'.

Oh well, still making pretty good beer. Another 30 lbs to go or so, then I'll replenish with the originally intended bohemian pils, which won my SMaSH base malt taste test last year in the pils category.

Doh. Slap on the (big) forehead.

I spotted a sack of the bohemian variety at Chicago Brew Werks in Plainfield when I was there a couple weeks ago, and realized the labeling for the bohemian says 'bohemian'. The one I got just says 'pilsner'.

Oh well, still making pretty good beer. Another 30 lbs to go or so, then I'll replenish with the originally intended bohemian pils, which won my SMaSH base malt taste test last year in the pils category.

Doh. Slap on the (big) forehead.

Wednesday, December 18, 2013

Mexico batch

Beer made at La Colmena, Mexico City. Brewed 12/13/13 as a beer making workshop.

3 gallons

3 lbs muntons light DME

8 oz mfb caramel 120

8 oz German dark Munich

SRM 15

Steep grains in muslin sack 30 mins at 150 df

Add DME, start boil at 3 gallons

Boil 60 mins

60 mins add 1/2 oz saaz 2.9%. 8 IBU

15 mins add 1/2 tsp Irish moss

10 mins add 1/2 oz northdown 8.6%. 8 IBU

Boil kind of weak, split between 4 pots

Chill in ice bath.

Add 1 gallon rinse water

Pitch with packet of fermentis safeale us-05

Leave in primary 2 weeks

Left instructions to bottle with 100 grams sugar.

Abv est 5.0. No Og readings.

Thursday, December 5, 2013

Going to Mexico

Leaving for Mexico next week. Alizarin asked me to teach her peeps how to brew. She asked for a list of equipment/supplies. I sent one, and she replied that it sounds complicated. She indicated, however, that they have friends who brew, so I figure that's a start.

I scoured the internet for brewing supplies in Mexico City, and found a single grain wholesaler. I'm hoping the friends who brew know of a shop.

Here's my plan: I plan to get a 3 gallon batch of some sort of amber ale into a fermenter and leave bottling instructions. I noticed a nice water carboy in the background while skyping, and figure they have a kitchen and probably an aggregate of 4 gallons of cooking pots, and access to bags of ice and bleach.

So the things I plan to bring are yeast, a 3 lb bag of dme, a pound of specialty malt (maybe 50/50 crystal120 and munich), and a couple ounces of hops. I hope they can locate a thermometer, some sort of clean cloth sack so I can steep the specialty malt at a reasonable temperature, and a hose to siphon with.

Sounds like a worthy way to spend time in Mexico City.

I scoured the internet for brewing supplies in Mexico City, and found a single grain wholesaler. I'm hoping the friends who brew know of a shop.

Here's my plan: I plan to get a 3 gallon batch of some sort of amber ale into a fermenter and leave bottling instructions. I noticed a nice water carboy in the background while skyping, and figure they have a kitchen and probably an aggregate of 4 gallons of cooking pots, and access to bags of ice and bleach.

So the things I plan to bring are yeast, a 3 lb bag of dme, a pound of specialty malt (maybe 50/50 crystal120 and munich), and a couple ounces of hops. I hope they can locate a thermometer, some sort of clean cloth sack so I can steep the specialty malt at a reasonable temperature, and a hose to siphon with.

Sounds like a worthy way to spend time in Mexico City.

Tuesday, November 12, 2013

Process

I am set up to make 2.5-3 gallon batches. I work in my kitchen. My stove top has a 17,000 btu/hr and a 15,000 btu/hr burner, which work pretty well for the volumes I work with. I cover the stovetop with foil to facilitate clean-up.

I usually prepare a yeast starter the night before brewing. I keep about 3/4 qt starter wort in the freezer from the previous week. I thaw this out on Thursday, then boil it on Friday, cool it in the sink, pour the liquid off the reclaimed yeast, then add the cooled wort to the yeast jar. I seal this up tight, shake it to aerate and break up the yeast cake, then leave the jar with a loose lid in the cupboard overnight, sitting in a bowl in case of a foamover.

Water comes from Lake Michigan, via Chicago's Jardine filtration plant, delivered to Oak Park. I have a 2 stage filter under the sink, cloth followed by carbon. For sanitation, I use household bleach, and prepare rinse water by boiling straight tap water in a teakettle, typically the night before.

Grind the grain straight into the mash tun. I also add initial salts into the mash tun with the grain. The most typical salt addition is 1/2 tsp CaCl, to bring up the Cl in the local water and reduce the bitterness from the low Cl/SO4 balance in Chicago water. Gypsum for hoppy beers, baking soda for roasty beers. I have some chalk available, but rarely use that.

Infusion mash, adding filtered tap water from brew kettle heating on the stove. I use a qt. pyrex pitcher to transfer the water.

I check the pH with paper, and occasionally add brewing salts if needed to get the pH correct. I stir the mash about every 15 mins (and add boiling water if needed to hold temp), and let rest lidded to convert.

Here's my homemade lauter manifold, I just stir the mash, drop this into the bottom, and siphon out wort over the side into the boil kettle. Always vorlauf using the quart pitcher, maybe one or two quarts.

Sparge and lauter are similar to infusion mash, I sprinkle hot (150-170 df) water (from another stock pot) over the grain bed with the pyrex pitcher, and use a c clamp to pinch the hose to control lauter rate. With no adjuncts, my efficiency is usually in the mid-80s. I use Brewersfriend for all recipe calcs, although I am currently beta-testing WORT, a new android app by +Joe P.

I weigh hops using my dial-a-gram from my ceramic studio.

My boil kettle is only 4 gallons, so I typically boil about a gallon of final runnings in a saucepan along side the kettle, especially for a 90 minute boil. I throw this into the kettle near the end of the boil, when there's room. I almost always add 1/2 tsp irish moss near the end of the boil, at 15 mins. I let the irish moss soak in 1/4 cup water for an hour or so before adding it to the boil.

My wort chiller is a single pass double coil, made from 50 feet of 1/4 inch copper tubing, and fittings for the kitchen faucet.

Chilling varies depending on the time of year and temperature of tap water. It can be as quick as 15 minutes, or as much as 30 minutes. I keep the spoon in there to stir periodically to keep the chill moving along.

Once chilled, I transfer wort into a milk jug in 3/4 gallon portions, give it a good shake to get aeration, then pitch into the fermenter through the straining funnel. I use a 6 gallon glass carboy for primary, which winds up being a little over half full. The last 3/4 quart dripping from the funnel goes into a mason jar then into the freezer, to be used as next week's starter wort.

Primary fermentation gets done on the basement floor or other locations in the house depending on temperature needs. I use a pan of water and towels for swamp cooling, or cover the carboy with a beach towel (or next to a radiator) to generate heat. I use ale yeast. Primary fermentation generally takes 1 week. I use 3 gallon glass carboys (I have two in rotation) for secondary fermentation, which generally takes 2 weeks. This schedule allows for a new batch every week, and pretty much no concerns about incomplete fermentations.

I reclaim yeast from primary fermentation. I wash the yeast using rinse water, transferring, settling, and pouring off between quart mason jars about 3 or 4 times, before refrigerating the final product. This jar is ready to pour the nice milky yeast solution off of the settled trub.

I keep yeast dedicated for each of my 4 core beers (wit, vienna, porter, and stout), plus I keep a house US-05 and S-04 available. I currently have a second wit yeast and a belgian trapist. I may dump the wyeast 3944 in favor of the 3942, depending on how the current batch with 3942 comes out. The 3944 is a little funky for me, hard to get the correct balance between phenols, diacetyl and esters.

Primary fermentation gets done on the basement floor or other locations in the house depending on temperature needs. I use a pan of water and towels for swamp cooling, or cover the carboy with a beach towel (or next to a radiator) to generate heat. I use ale yeast. Primary fermentation generally takes 1 week. I use 3 gallon glass carboys (I have two in rotation) for secondary fermentation, which generally takes 2 weeks. This schedule allows for a new batch every week, and pretty much no concerns about incomplete fermentations.

I reclaim yeast from primary fermentation. I wash the yeast using rinse water, transferring, settling, and pouring off between quart mason jars about 3 or 4 times, before refrigerating the final product. This jar is ready to pour the nice milky yeast solution off of the settled trub.

I keep yeast dedicated for each of my 4 core beers (wit, vienna, porter, and stout), plus I keep a house US-05 and S-04 available. I currently have a second wit yeast and a belgian trapist. I may dump the wyeast 3944 in favor of the 3942, depending on how the current batch with 3942 comes out. The 3944 is a little funky for me, hard to get the correct balance between phenols, diacetyl and esters.

Here's a bottling picture. I use my mash tun as a bottling bucket. Rack from secondary onto priming solution, then use racking cane with bottling wand. I use 1/3 cup +/- table sugar boiled in a couple cups of filtered water per batch, more for more carbonation, less for less, but always between 1/4 and 1/2 cup.

These are ready for the capper, I use a black hand held capper, which occasionally breaks bottles. The yield for a typical batch is between 25 and 30 bottles, 12 oz each. I have some 22 oz bottles in rotation, and a few 550s as well.

Usually on brew day, I start some sourdough bread by throwing a couple cups of spent grain and a cup of final runnings into the blender, then liquifying it. To this I add flour, salt and sourdough starter to make bread.

Monday, November 4, 2013

Tuesday, October 22, 2013

Brixies Brewers Dream

So I have this dream last night. Someone calls me and tells me there is a club meeting, so I go. The meeting is at this sort of country club type of place, only with horses. Most of the people in the club are renting horses, and riding horses. I am unprepared, and can't figure out how to get ahold of a horse myself, although I kind of want to ride, even though I don't know how. I figure I can just fake it or figure it out by watching other riders. Since I can't get a horse, I hang out with the guys who aren't riding.

The riders ride in a circle, then they take off for a fox hunt or something. Someone in the group I'm with comments on how difficult and cool it is to ride fast in a group like that.

I look at the agenda, and realize the beer part of the meeting isn't until late at night, and I need to get home to bed. So I leave early.

Strange yet vivid dream.

I guess I do care that I didn't get any recognition in the Brixtoberfest contest. Next year I'll have to plan something good.

The riders ride in a circle, then they take off for a fox hunt or something. Someone in the group I'm with comments on how difficult and cool it is to ride fast in a group like that.

I look at the agenda, and realize the beer part of the meeting isn't until late at night, and I need to get home to bed. So I leave early.

Strange yet vivid dream.

I guess I do care that I didn't get any recognition in the Brixtoberfest contest. Next year I'll have to plan something good.

Thursday, October 10, 2013

Opening entry

I'm expecting to keep notes on beer making here. Hopefully this will replace the spiral-bound notebooks I've been using.

I should give some thought to organization here. I know the notebook is chronological like a blog. I would also like to sort entries by other categories, and retrieve things easily as well, so I suppose I'll be playing with labels quite a bit.

So far, so good.

I should give some thought to organization here. I know the notebook is chronological like a blog. I would also like to sort entries by other categories, and retrieve things easily as well, so I suppose I'll be playing with labels quite a bit.

So far, so good.

Subscribe to:

Posts (Atom)