Today I am starting a lager, and took some pictures to document the day. Many things have changed since I started 5 years ago, but many stay the same.

For starters, I now use this kitchenaid mill attachment to grind my grain. I use the coarsest setting, which gives a consistent pretty fine crush, with good efficiency and minimal stuck sparge. Downside is the cup only holds about a pound of grain, so I have to keep feeding it off the scale every few minutes.

I still just use a pot on the stove as my HLT, and transfer infusion water into my tun on top of the grain with a quart pyrex pitcher. Typically I heat the HLT to about 15 df above my first rest temperature, then bring it to a boil to infuse to higher rest temps. Any salts go into the grain/mash, where I sometimes test the pH. I use CaCl, gypsum, or baking soda, depending on the application. I love the stainless spatula for stirring in the mash, which I have used since day 1. I also now have a homemade maple wooden spoon that I use for larger mashes when the stainless doesn't reach the bottom .

I still use the lauter manifold I built when I first started, it works great in the gott cooler I use as the mash tun. Sparge water is transferred using the pyrex pitcher from the 170 df HLTs. I vorlauf about 3 or 4 quarts, depending on how the wort looks.

For this batch, there is a lot of pils, so I want to drive off as much dms as I can, so I use 2 pots for a good portion of the boil. The biggest stove burner is 17,000 btu/hr, which produces less than the roiling boil I prefer for 5 gallons. It works great for 3 or 4 gallons, but 5 gallons is more of a simmer. With 2 row or maris otter, the one big pot is fine, but pils, splitting is better. Also, I typically use 3 burners to get it up to a boil, which otherwise takes forever.

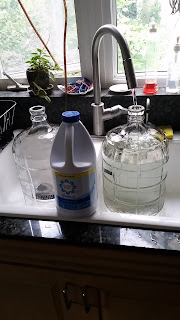

I use bleach for sanitizing on brew day. I came full circle, using starsan for a while, but started having way too much contamination because it doesn't clean, it only sanitizes. With bleach, when you leave things soaking for 20 minutes, they come out clean. With starsan, things had a coating of beer on them, so I really should have added pbw or something to the cleaning process if I wanted to continue with it. I still use it for bottling, but I am careful to brush out bottles before putting them in storage. Note I also still use glass carboys for fermentation. I have cracked a couple over the years, but with careful handling, I feel better about them being clean.

Here's an addition for lagering, a pre-chiller coil. I have a copper coil in an ice bath that chills the tap water before it gets to the wort chiller. In winter months, I can get down to the mid 50s, but in summer, it is still a push to get below 70 df with tap water for chilling.

I still aerate wort for pitching in the same costco milk jug I have used since day 1, about 25 shakes of a half-ful jug does the trick.

I now have 2 fermentation chambers in the basement. The first is an old ice-cream freezer that I use for lagering only, it holds up to 3 3-gallon carboys. It is only set up to cool, it doesn't warm. The second unit is a college-dorm fridge with a plywood case extending the front, it holds 2 5-gallon carboys, and can either chill or heat, as I added a reptile heater bulb into the side of the box. The temp controls are just two generic fish-tank controllers rigged to hold the appropriate temperature. I can have up to 19 gallons in fermentation at any time, but usually have 11 or so, 2 carboys in each chamber.

I bought a funnel-filter to filter out wort from the trub in the bottom of the pot. Sometimes it takes overnight.

While I still bottle using table sugar as primer for natural carbonation, my latest toy is this keezer I bought second-hand from a guy for $550 and some homebrew. I priced out the components, which added up to about $1000 worth of stuff, so I think I did OK. I bought the kegs separately. Kegging is way easier and makes better beer. Any beer that is good cold goes into a keg.

So now I make 5+ gallon batches, maybe every 2-3 weeks. I am a lot more confident on my recipes, and rarely have a batch that I have to choke down, although it still happens occasionally.

No comments:

Post a Comment